How sustainable paint is made

Sustainability has always been the main principle of Tikkurila’s product development, which is why the pioneering company is ranked in the EcoVadis business sustainability rating among only 4% of the companies in the paint industry. An RDI Manager with a prestigious 25-year career in product development explains the recipe for sustainable paint.

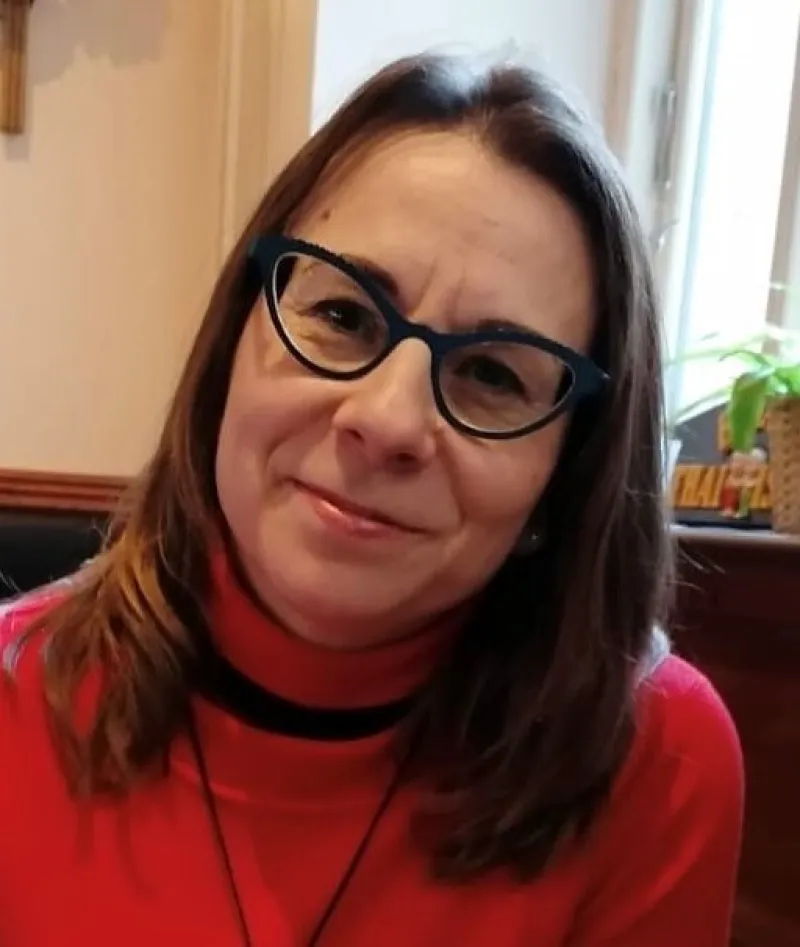

Heidi Helkamo from Tikkurila’s international Interior Deco Products has gained an extensive overview of the development of paint products over her 25-year career. Throughout these years, paint products have evolved to be more protective and environmentally friendly, but the main principle of research and development remains the same.

“Sustainability has been the main driving force from the very beginning. All product development projects start with setting a goal. The goal can be, for example, that the product passes the demanding criteria set for a certain ecolabel or that the product contains the smallest amount of solvents possible. However, the most important thing is that the paint does what it is supposed to do as well as possible: the primary job of paint is to not only protect but also enhance the surface beneath it with long-lasting effects. This has a great impact on the product’s environmental goals: the longer the life cycle is which is provided by the paint to the surface, the more sustainable the product will be. We always pay close attention to this when we evaluate the final result,” she says.

Ecolabels provide the framework for product development

It is also thanks to sustainable product development that most Tikkurila products have passed the demanding criteria set for first category ecolabels and other certifications. These labels include, for example, the Nordic Swan Ecolabel, the EU Ecolabel and M1 classification that do not only inform consumers that the products are sustainable – i.e. environmentally- or user-friendly – but they also ultimately define how the products are designed.

“Ecolabels largely define the framework for the product development process: what raw materials the paint can contain, what type of product packaging should be used and what the instructions are that need to be provided to consumers. We have also started using the international EcoVadis system through which we can monitor the sustainability of our raw material suppliers, for instance. This allows us to get a better picture of the sustainability of our entire range of suppliers and what are the most critical aspects of a product’s life cycle. Tikkurila is ranked in the gold category that includes only 5% of all companies and 4% of the companies in the paint industry.”

Sustainability is present in all phases of the process

According to Helkamo, sustainability is present in real life in all phases of the product development process, which is why it may take several years for a product to advance from product development to being sold to consumers.

“First, we need detailed documents about our raw materials that prove that they can be used in products equipped with ecolabels. During the process, different versions of the paint are made to gain the desired qualities. After this, we will prepare a test batch and send a sample to an impartial third-party laboratory to be tested. The purpose of these tests is to find out the amount of solvents the product contains or how much emission it releases into indoor air, for instance. The results are needed in applying for ecolabels such as the EU Ecolabel and other certificates, and at least six months must be allocated for these application processes,” she says.

Bio-based paints are a hot topic in the industry

Tikkurila’s long-term development work has yielded results as about 80% of the company’s production consists of waterborne paints. At the moment, the trend of product development is focused on bio-based products that have some of their fossil-based binders replaced with bio-based binders. For Helkamo, the development of bio-based binders is an example of how diverse the work is and why she started as a researcher at Tikkurila after graduating from the Helsinki University of Technology.

Helkamo has a track record of being involved in developing bio-based paints, for example, the recently launched Tikkurila Harmony Care decorative paint. 30% of the paint’s fossil-based binders have been replaced with bio-based binders. Instead of crude oil, bio-based binder is made from environmentally friendly raw materials, such as plants, seeds and various materials of agriculture.

“Looking back, we have taken major strides in moving from solventborne paints to waterborne paints. Currently, we are gradually moving from fossil-fuel based binders to bio-based binders. Another interesting challenge for product developers is the development of new functional products. A trivial example is chalkboard paint, which is not only paint, but serves as a chalkboard as well. This is also an example of what makes this job so interesting,” says Helkamo.

Another example of functional solutions are the paint solutions that provide the customer’s process with a quality that reduces their environmental impact. This can occur, for example, as a result of reduced energy consumption through boosting the customer’s process or reduced volumes of washing liquids resulting from easier cleaning of surfaces.