Temazinc 77

Zinc rich primer, Matt

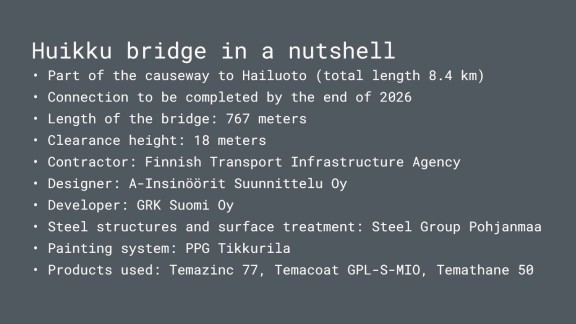

In the future, you will be able to drive to Hailuoto when a causeway is built between Riutunkari in Oulu and Huikku on Hailuoto Island.

Life on Hailuoto Island, located off the coast of Oulu, will change when a causeway of 8.4 kilometers becomes available to the mainland at the end of 2026. The connection will be implemented under the Finnish Transport Infrastructure Agency's alliance model, including not only the causeway but also the bridges of Huikku and Riuttu, with GRK Suomi Oy as the contractor.

There are over 10,000 square meters to be painted on the bridge. The steel blocks will be painted with three different types of paint. In total, they will receive five layers of paint, which amounts to a total painted surface area of 50,000 square meters. The parts of the bridge are painted at our factory. To meet the quality requirements of the Finnish Transport Infrastructure Agency, it is painted with five coats. We use weather-resistant steel for the bridge. This provides the structure with a longer maintenance interval.

It is important for us that the cooperation runs smoothly. PPG Tikkurila helps us a lot, especially in developing the painting process.

You’re visiting Tikkurila website from United Kingdom. Would you like to visit the local UK site?