The world's leading manufacturer of agricultural machinery

In the expanses of Ylivieska, you will find the world's leading manufacturer of agricultural machinery for processing and preserving feed grain: Aimo Kortteen Konepaja Oy, which has been manufacturing roll mills, feed mixers and feeding systems since 1969. During its 50-year journey, the company has specialised in product technology that saves energy and the environment, facilitates agricultural work as well as improves the profitability of farms, not only in Finland but worldwide.

"Since the 1980s, most of our agricultural machinery has been exported, mainly to Europe and Russia, but also further, for example to Japan," says Jari Rönni, Purchasing Manager at Aimo Kortteen Konepaja.

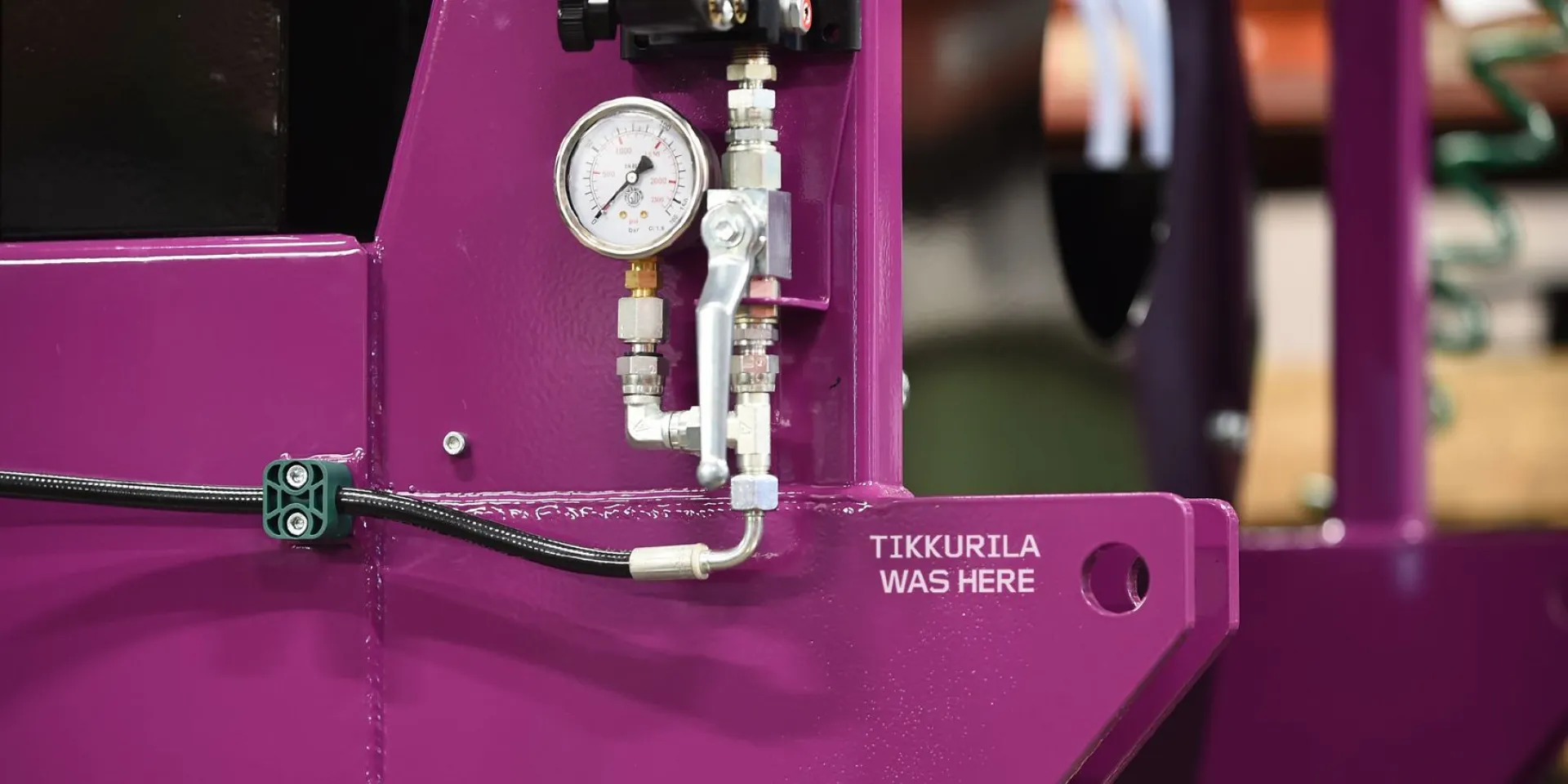

Cooperation with Tikkurila is also long-standing. Although the company has used other paint suppliers over the years, Tikkurila was involved in the start-up of the company – and the recognisable purple colour of the equipment manufactured by the workshop was also tinted by Tikkurila.

Additional capacity with an efficient painting method

Around 2020, the capacity of the paint shop connected to Aimo Kortteen Konepaja production facility was beginning to reach its limits – a solution was needed that would provide both a high-quality result and faster throughput of components in the painting line.

Temasilox is a two-component, high-gloss polysiloxane topcoat with excellent colour tone and gloss retention. As a single-coat paint, it provides faster throughput and withstands mechanical stress well without rusting, fading and scratching.

"Thanks to Temasilox paint, items go through the paint shop much faster, which made production assembly even smoother. The end result is also of high quality: appearance and durability are now better than before. This is important because the service conditions of the machines place heavy demands on surface treatment: the painted surface must withstand varying weather, repeated washing and UV stress," Rönni says.

"Temasilox allows a harder surface than traditional single-coat paints. A durable surface minimises scratches from storage, stacking and assembly, which in turn reduces the need for after-treatment. Faster drying time also saves energy," adds Johannes Vähänen, Key Account Manager at Tikkurila.

A solution also for a healthier working environment

As the painting line is located in a large production hall where the equipment is also assembled, it is important that the products used do not release emissions to the surrounding area.

"Unlike most traditional single-coat products, Temasilox does not contain isocyanates. Thanks to its high non-volatile content and low VOC content, Temasilox meets even the most demanding environmental requirements. It also has a milder scent," Vähänen says.

"Occupational safety is important to us. It is great that, in cooperation with Tikkurila, we found a product that is efficient in terms of technical properties and also low-emission and environmentally friendly," Rönni sums up.