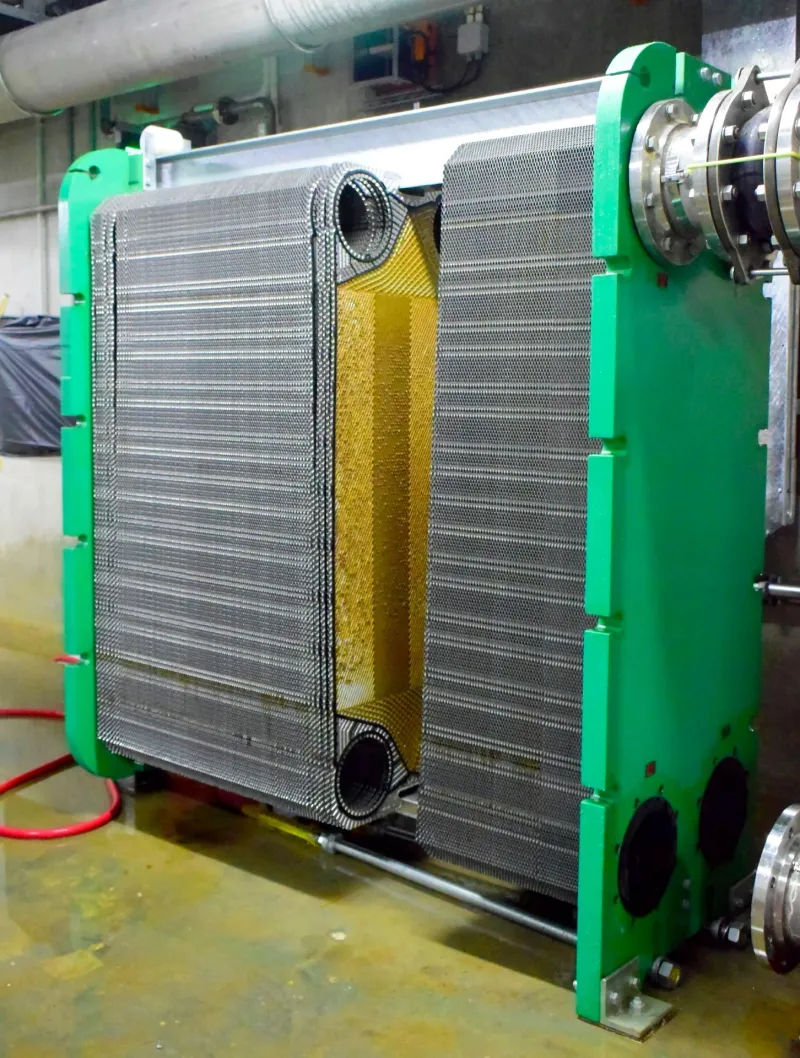

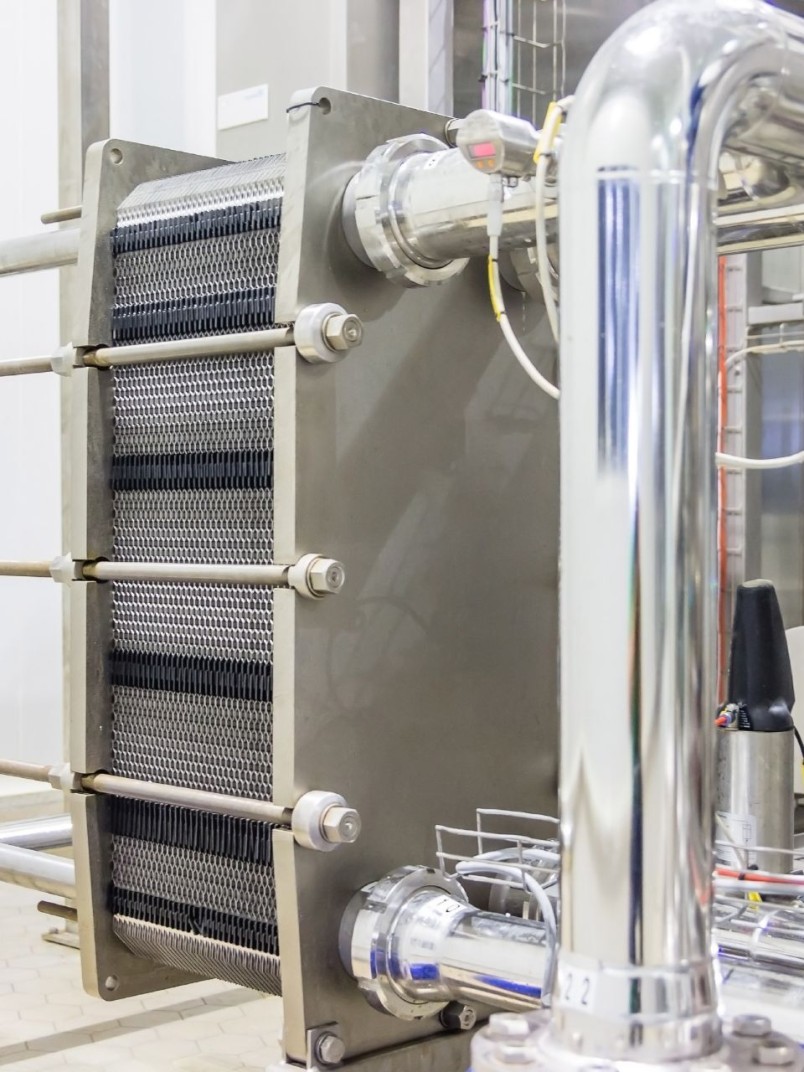

Industrial coating solutions for heat exchangers

Tikkurila has been cooperating with a leading global provider of heat exchangers for over 20 years, delivering high-quality, sustainable and customised industrial coating solutions that have helped the partnership go from strength to strength. Whatever your requirements, we work together to help you find the right solution, with technical advisory and support available every step of the way.

Specialised solutions for unique challenges

Heat exchangers undergo moderate mechanical and chemical stress in operation, so coatings need to provide excellent resistance to protect the equipment’s surfaces.

Our high-quality coatings also meet the highest hygiene requirements – another essential requirement for this application area. Many of our customers require tailored solutions, so we work together to develop bespoke products that meet unique technical requirements, are faster and easier to apply, or more cost efficient.

Sustainability is our speciality

We offer a full range of more sustainable solutions, from water-borne coatings such as Fontecoat FD series to direct-to-metal (DTM) products with a high solids content. These more environmentally friendly alternatives can help you to meet your sustainability targets.

All our products are dependable, stable and high quality, and customers benefit from on-time deliveries via our wide international distribution network.

Thorough testing for peace of mind

Tikkurila coatings are thoroughly tested before being made available to customers. We also work with our customers to facilitate any customer-specific tests that may be required.

Succeeding together

We work closely with you to understand your needs throughout the lifecycle of your assets, identifying opportunities where we can improve efficiency by reducing costs, accelerating project schedules and carefully managing the supply chain.

Our technical services experts can help you to select the right painting systems for your application, as well as providing painting shop audits to improve and streamline your application process and ensure a high-quality surface treatment. Whatever your challenges, we are ready to support you in achieving your business goals.

Want to hear more about our solutions? Tikkurila's experts are always here to help you find the right product or solution.

Tests and standards

- Accelerated corrosion tests (ISO 12944, customer specific tests)

- Mechanical resistance