FAQ – Fire protection for interior wooden surfaces

Wood construction is on the rise, with many beautiful and sustainable wooden apartment buildings, libraries, and schools built in recent years. Regulations regarding wood construction, including fire safety, have been updated over the years. This FAQ provides answers to many of the most frequently asked questions about fire protection and fire-retardant products used for industrial wood coatings for interior wooden structures.

Do you want to know more? Please subscribe to our newsletter and stay up-to-date with our latest news.

Subscribe to our Newsletter

Which wooden surfaces need fire protection?

Wood can be used as a construction material without fire-protection treatment. However, depending on the site and customer requirements, treatment can make the building safer. This extra protection enables a wider use, for example in the following types of buildings:

- Schools, kindergartens, and assisted-living facilities

- Storage facilities

- Detached houses, terraced houses, and apartment buildings

- Offices

- Hotels

- Libraries

- Annexes or extra floors with wooden frames

What are the benefits of using fire-retardant products?

Fire retardants slow the ignition of wood and the spread of fire, while also creating less smoke than untreated wood. This provides valuable extra time for people to escape and for emergency services to reach them, while reducing the effects of smoke inhalation.

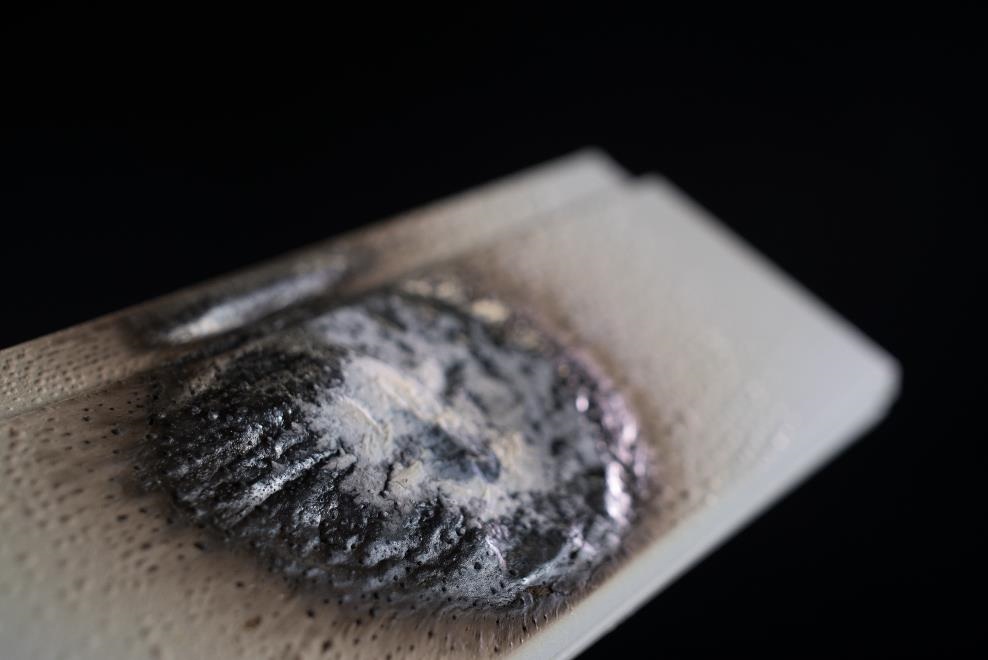

How do fire retardants work?

When exposed to heat, fire-retardant material undergoes a reaction causing it to expand and char, forming an insulating layer on the wood. The porous foam layer insulates the wood from the flames, preventing the wooden surface from heating up rapidly or catching fire. This is known as intumescent technology, i.e. fire protection based on the paint surface expanding when exposed to heat.

Tikkurila’s fire-retardant products carry the B-s1, d0 fire safety classification. What does this mean?

B-s1, d0 is the best possible fire-safety classification for wooden materials. Construction products and building elements are divided into various fire classifications according to the EN 13501-1 European fire safety standard. The classification also includes an A class, reserved for non-combustible materials such as steel.

Here’s a more detailed listing of the fire classifications for construction materials:

Construction materials are labeled with the following markings, with the exception of flooring: A1, A2, B, C, D, E, F.

Smoke emission and flaming droplets are identified with the extra classification “s” and “d”. For smoke emissions the classifications are s1, s2, and s3, and for flaming droplets d0, d1, and d2.

A1 = Materials that do not contribute to fire at all (non-combustible materials)

A2 = Materials with extremely limited contribution to fire

B = Materials with very limited contribution to fire

C = Materials with limited contribution to fire

D = Materials with acceptable contribution to fire

E = Materials with acceptable fire behavior

F = Materials with no defined type of fire behavior

s1 = Very low smoke emission

s2 = Low smoke emission

s3 = Smoke emission does not meet s1 or s2 requirements

d0 = No flaming droplets or particles

d1 = Flaming droplets or particles burn out fast

d2 = Production of flaming droplets or particles does not meet d0 or d1 requirements

Source: E1 National Building Code of Finland

Can fire retardants be used with all types of wooden surfaces?

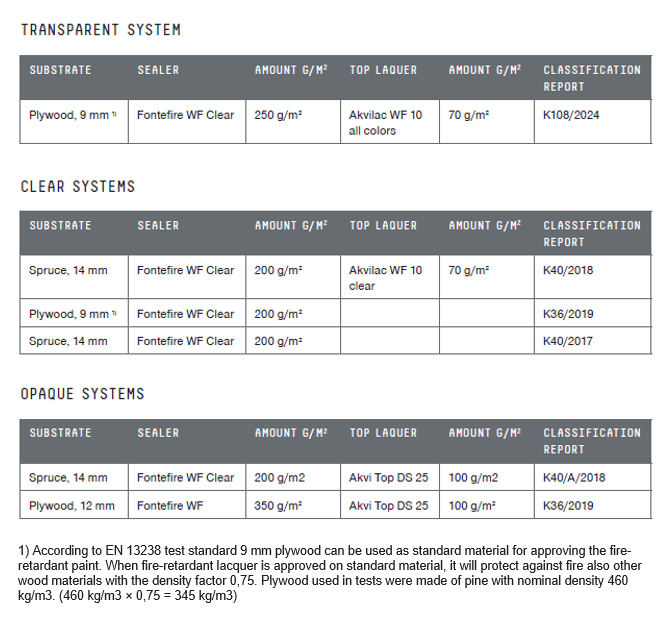

Fontefire WF Clear is tested on standard 9 mm plywood according to EN 13238. When fire-retardant lacquer is approved on standard material, it will protect against fire also other wood materials with the density factor 0,75. Plywood used in tests were made of pine with nominal density 460 kg/m3. (460 kg/m3 × 0,75 = 345 kg/m3).

For less-common types of wooden material, please get in touch with a Tikkurila expert before applying a fire-retardant paint.

What are the painting systems that fulfill the B-s1, d0 according to EN 13501-1 European fire safety standard?

Are fire-retardant paints and lacquers environmentally friendly?

Yes, Tikkurila fire-retardant products are waterborne, they cause less emissions and are environmentally friendly and safe to use.

Fontefire WF Clear, top lacquer Akvilac WF 10 and top paint Akvi Top DS 25 meet the stringent requirements of the M1 certification.

Can a wooden surface be painted first and then the Fontefire WF Clear fire-retardant lacquer applied on top?

No, you must apply Fontefire WF Clear directly onto the wood without any priming lacquers in order to meet the requirements for the B-s1, d0 surface classification.

Fontefire WF Clear is transparent white. Tikkurila’s fire-retardant products are intended to be applied directly onto the wood. If surfaces are first painted or the fire-retardant product is tinted, the fire-retardant properties will not necessarily work as intended. Additionally, the Fontefire WF Clear lacquer may alter the color of the underlying surface, which is not necessarily what the customer wanted.

Can Fontefire WF Clear lacquer be tinted?

Fontefire WF Clear cannot be tinted. The fire-retardant classification is only approved for clear lacquer, not tinted.

Can Akvilac WF 10 surface lacquer be tinted?

Akvilac WF 10 can be tinted to all transparent colors according to the Tikkurila Interior wood stains and lacquers colour card.

What color is Fontefire WF fire-retardant paint?

Fontefire WF paint is light gray, adding to the covering properties of the entire paint surface.

Can you paint over Fontefire WF products with any paint?

You cannot paint over Fontefire WF products with any paint. The fire-retardant classification is only retained if one of the following products is used as a topcoat:

- Chemical-resistant top lacquer Akvilac WF 10 for surfaces that will be exposed to wear or abrasion

- Akvi Top DS 25 acrylate topcoat

Do fire-retardant products always need to have a topcoat?

If a fire-protected surface needs to be abrasion resistant, it should be finished with a top lacquer or paint. Indoors, a fire-retardant lacquer alone is enough for wood surfaces that are not subject to wear, such as ceilings.

How should fire-retardants be applied in industrial applications?

The products can be applied with vacuum application and spraying. Before application, always check the technical datasheet and system sheet for more information.

Can you paint with Fontefire WF Clear on-site?

Our fire-retardant products have been developed for both industrial and on-site painting. Industrial means that the surface treatment occurs at the factory under controlled conditions, and it can also be applied on-site, providing the same level of protection as if it were painted in the factory.

If there is an air gap in the structure, can panels or boards be treated with Fontefire WF Clear fire retardant?

Yes. The B-s1, d0 approval is valid for structures with or without air gap. For special circumstances please always consult a local fire protection specialist.

Do you want to know more? Please subscribe to our newsletter and stay up-to-date with our latest news.

Subscribe to our Newsletter