GrafoTherm – Anti-condensation coating

GrafoTherm is a one-component water-borne anti-condensation coating for steel roofing sheets, steel structures and other metal surfaces, where condensation and dripping-water problems occur. Exactly like BioRid, GrafoTherm is also built up on millions of micropores in the sizes 0.1–100 microns. They form a multi-layer, porous texture with excellent moisture-absorption capacity.

Evaporation occurs faster than with ordinary coatings due to the microporous structure, which breaks water surface tension and spreads moisture all around.

Other properties

Heat insulation (λ = 0.085 W/mK) and noise damping are other important functions of GrafoTherm. By forming a relatively thick layer the coating slows down rapid changes in the surface temperature. Thus the surface temperature of e.g. profiled steel on the roof does not drop so quickly below the dew point in the night time. During hot summer days it also insulates surfaces and keeps them cooler.

Application

Typical application areas for GrafoTherm are warehouses and parking houses, ventilation ducts and water production plants, other production facilities and sport arenas, interior surfaces of wind turbine towers, sea containers, train and goods wagons, animal sheds, etc.

The best results with GrafoTherm can be obtained by spraying, but it can also be applied by brush or roller.

There is a special version for production line spray application – GrafoTherm Line.

|

Product name |

Specific gravity |

Theoretical coverage |

Water absorption |

Application methods |

Colors |

|

GrafoTherm |

1,1 kg/l |

1,1-1,8 m2/l |

approx. 350g/m2 of water, 900 g/m2 wet (NF P 15-203-1) |

Airless spray, brush and roller |

White and gray |

|

GrafoTherm Line |

1,05 kg/l |

0,9-1,8 m2/l |

approx. 370 g/m2 of water, 600 g/m2 wet (NF P 15-203-1) approx 650 g/m2 of water, 1200 g/m2 wet (NF P 15-203-1) |

Conventional spraying or plaster spray gun |

White and gray |

See how GrafoTherm works

Example of the working principle of GrafoTherm

The pictures demonstrate the condensation cycle occuring in an uninsulated building with a roof made of partly GrafoTherm-treated and partly untreated steel sheets.

The example shows a normal early-spring or late-autumn day.

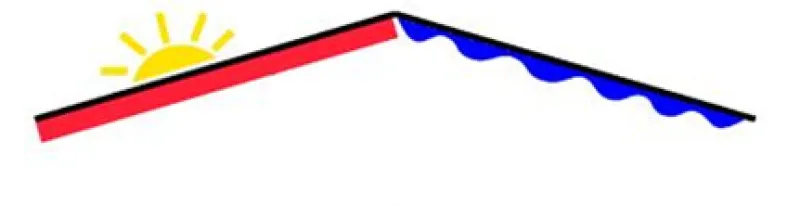

Phase 1 – Evening

The sun sets and the outdoor temperature falls rapidly.

The temperature of the roof will soon reach the dew point, and condensation starts to appear on the untreated part of the roof.

The GrafoTherm coating insulates and reduces the temperature difference between the steel sheets

and the air. No condensation therefore appears

on that part of the roof.

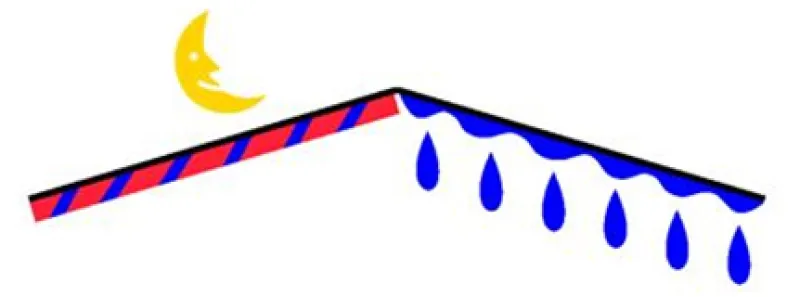

Phase 2 – Night

During cold nights with a clear sky, the temperature of a steel roof can be considerably lower than that of the outdoor air. This is due to long-wave heat radiation from the roof to the sky.

Heavy condensation now appears on the untreated surface and water starts dripping. Condensation also occurs on the steel surface under the GrafoTherm coat. However, condensation cannot take place on the surface of the GrafoTherm coating.

The micropores of the GrafoTherm coating adsorb the moisture and distribute it over the whole surface, where it is temporarily stored and even evaporates, if the conditions change.

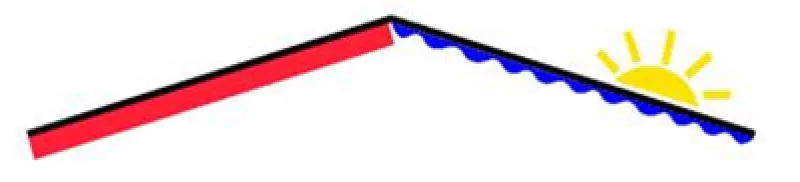

Phase 3 – Morning

The sun rises and the outdoor air is warmed up. The temperature of the steel roof will soon exceed the dew point. The untreated steel surface gradually stops dripping water and becomes dry.

The GrafoTherm coating will become dry very rapidly and will very soon have regained its capacity to meet the next condensation period.

Due to the size of the micropores, the surface tension of water is broken, and the moisture evaporates two to three times faster than it would on the untreated steel surface.